Sheroz Earthworks - Questions

Sheroz Earthworks - Questions

Blog Article

Sheroz Earthworks Fundamentals Explained

Table of ContentsThe Facts About Sheroz Earthworks RevealedEverything about Sheroz EarthworksFacts About Sheroz Earthworks UncoveredThe Facts About Sheroz Earthworks UncoveredExcitement About Sheroz EarthworksNot known Factual Statements About Sheroz Earthworks

Today, Smart Construction Remote links over 700 makers on jobsites to offices, saving hundreds of hours formerly spent by jobsite supervisors, property surveyors and designers travelling from workplaces to jobsites. To summarise, the first 10 years of Komatsu's smart maker control have actually been marked by a years of one-of-a-kind advancement, constant learning and advancement with customers.

Below's to the following ten years! Material generated in organization with Komatsu.

In the swiftly evolving globe of building and construction, precision and performance are necessary. 3D machine control, a system that utilizes GPS and various other sensing units to assist machinery with identify precision, is revolutionising the sector - https://www.abnewswire.com/companyname/sheroz.com.au_142204.html#detail-tab. From its early days of 2D guidance, this technology has progressed dramatically, making tasks that as soon as required manual intervention now feasible with minimal human input

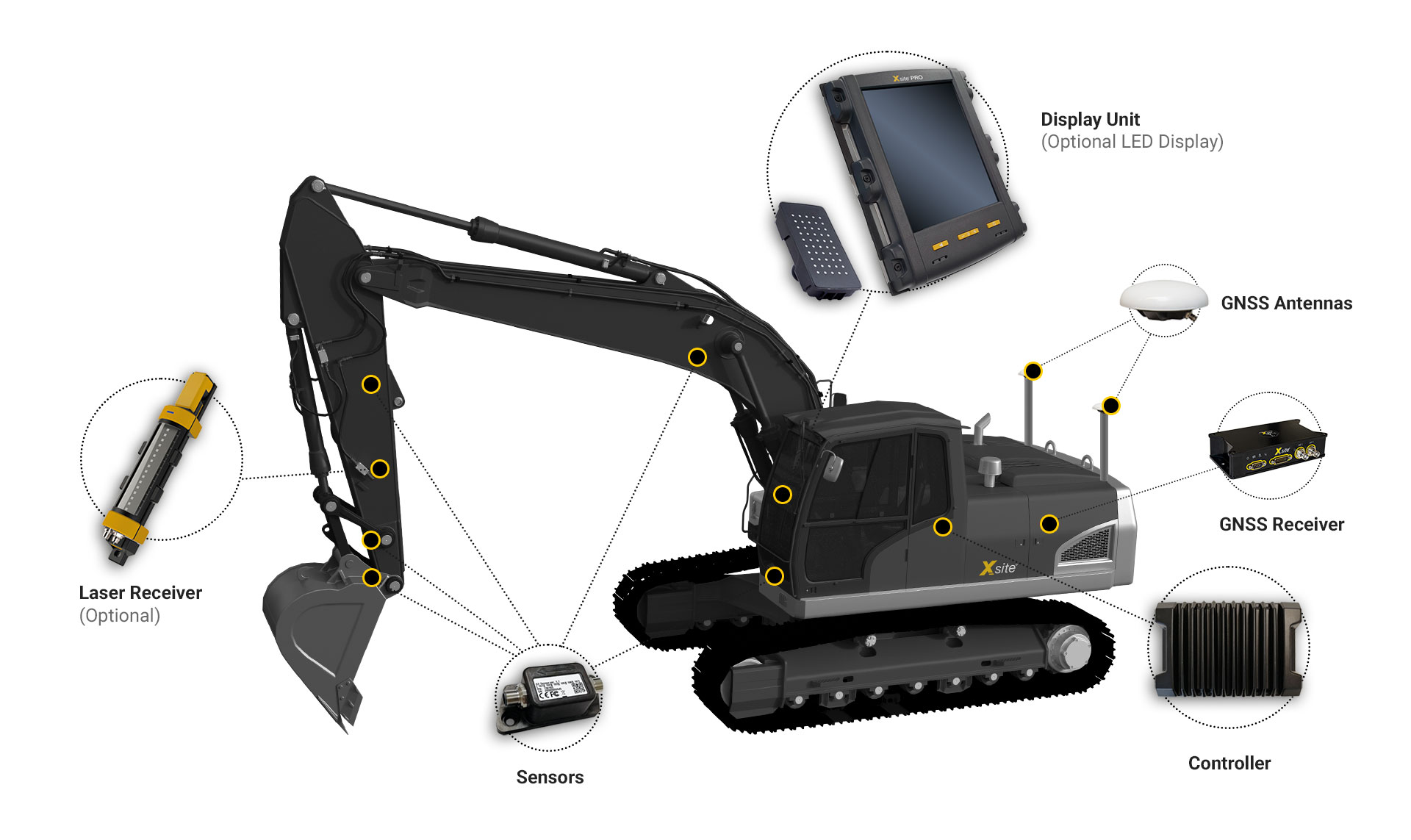

In construction, it makes certain that every cut, fill, and quality is implemented with surgical precision. Allow's discover how this game-changing technology works. At the core of any type of 3D machine control system are GNSS receivers and antennas, catching satellite signals to figure out the equipment's precise area. Onboard computer systems and control boxes process this data and interact with the equipment.

5 Simple Techniques For Sheroz Earthworks

This consists of establishing up GNSS receivers, calibrating sensing units, and configuring the equipment control software program. When established up, the system is integrated with existing machinery for real-time modifications and support. The magic of 3D maker control hinges on its real-time data collection and handling. GNSS and other sensing units continuously collect setting information, which is corrected for mistakes to supply reliable and specific support.

Individual interfaces offer real-time updates on the equipment's setting and needed modifications, ensuring exact control. Several factors impact accuracy, consisting of satellite signal high quality and sensing unit calibration. Techniques like Real-Time Kinematic (RTK) positioning and Exact Factor Positioning (PPP) improve accuracy, making sure the highest precision. In construction, 3D maker control is made use of for earthmoving, grading, paving, and excavation, making certain jobs are completed to precise specs.

The Best Strategy To Use For Sheroz Earthworks

3D machine control considerably enhances efficiency by minimizing rework and reducing material wastefulness, resulting in faster and much more affordable task conclusion. The innovation ensures every task is performed exactly as intended, causing continually high-grade job. Among one of the most compelling advantages of 3D machine control is the significant price savings it provides.

Fuel intake is optimized due to the fact that machines run a lot more efficiently and prevent unnecessary activities. Upkeep expenses are also decreased, as the machinery experiences less wear and tear as a result of precise operation. On the whole, these cost savings add to a much more lucrative profits for any type of task. By reducing human mistake and limiting direct exposure to harmful environments, 3D equipment control boosts employee security and reduces mishaps.

From building and construction to mining, this technology ensures tasks are carried out precisely and securely, decreasing prices and improving outcomes. As developments proceed, the possibility for 3D device control to even more enhance efficiency and security expands. Accepting this modern technology is important for sector experts aiming to stay competitive and achieve the highest requirements in their jobs.

The Only Guide for Sheroz Earthworks

Discover the future of precision and performance currently! Check out our most current YouTube video on the FJD H36 Motor Control System to see the innovation in activity: Enjoy now.

Over the years, we've seen operators with whole lots of experience do some remarkable points with their makers. Maybe they have an eye for adjustments that boost accuracy, or maybe they understand which attributes of their machine to make use of and when to improve efficiency or effectiveness - https://qualtricsxmkpyy9kbs2.qualtrics.com/jfe/form/SV_3IOcfD5rXwnI6x0. With today's advancements in hefty devices modern technology, also skilled operators can benefit from a real-time aid to improve their day-to-day efficiency.

This is where equipment control systems variable in. Some excavators come with equipment control systems that lead the operator via features to automate the excavating process.

Get This Report about Sheroz Earthworks

With this added precision, rework is basically eliminated, permitting the operator to finish the job promptly and move to the next job. For those dealing with dangerous or hard jobsites, remote-controlled options open new possibilities. This impressive add-on enables you to operate an excavator from a range in locations with hazardous materials (like in a potash mine) or poor ground conditions (like mud).

Maker control systems provide useful advantages to more than simply excavator operators. If you have actually a truck come in with a target of 23 lots, your operator can load their pail and dynamically weigh itoften without also being stationary.

This suggests the driver can see the exact weight of the lots they will discard (topcon gps). On-board considering provides real-time insight into the bucket's lots to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building EquipmentIf they discharge 12 bunches on the very first pass, the following pail requires to consider 11 tons

Sheroz Earthworks for Beginners

Many procedures use an on-board weighing app to make sure that the load is exact prior to they send their vehicles to the ranges, which is necessary because the range weight is what's utilized for payment and invoicing objectives. A number of producers consist of some kind of considering program on their loaders. Some additionally have functions that permit firms to monitor and regulate the total tons of find more information multiple vehicles.

Report this page